Concept Appassionato for Boretti by Jeroen van Rijnberk

PASSIONE IN CUCINA

Starting point for the project was the Appassionato concept for Boretti. The new kitchen counter included hidden induction stovetops under a marble surface. Being able to place your pans anywhere gave a sense of freedom while cooking.

Passione in Cucina (passion in the kitchen) was the driver behind this project. It gave shape to the initial concept and subject of this project: the embodiment of the kitchen control unit.

LIKE A GAS STOVE

The key challenges for this project were defined through combining the organisation’s and users’ needs. These were uncovered through user tests with initial prototypes

Fitting product interaction and aesthetics

Cognitive ergonomic design

Manufacturability

Aesthetics ideation

Interaction ideation

Interaction testing

Aesthetics ideation

Interaction ideation

Interaction prototype

FIT THE ITALIAN PASSION

Numerous rounds of prototyping interactions led to an interaction that fits the italian passion for cooking. The cycle of drawing, building and testing allowed us to explore a plethora of looks and interactions.

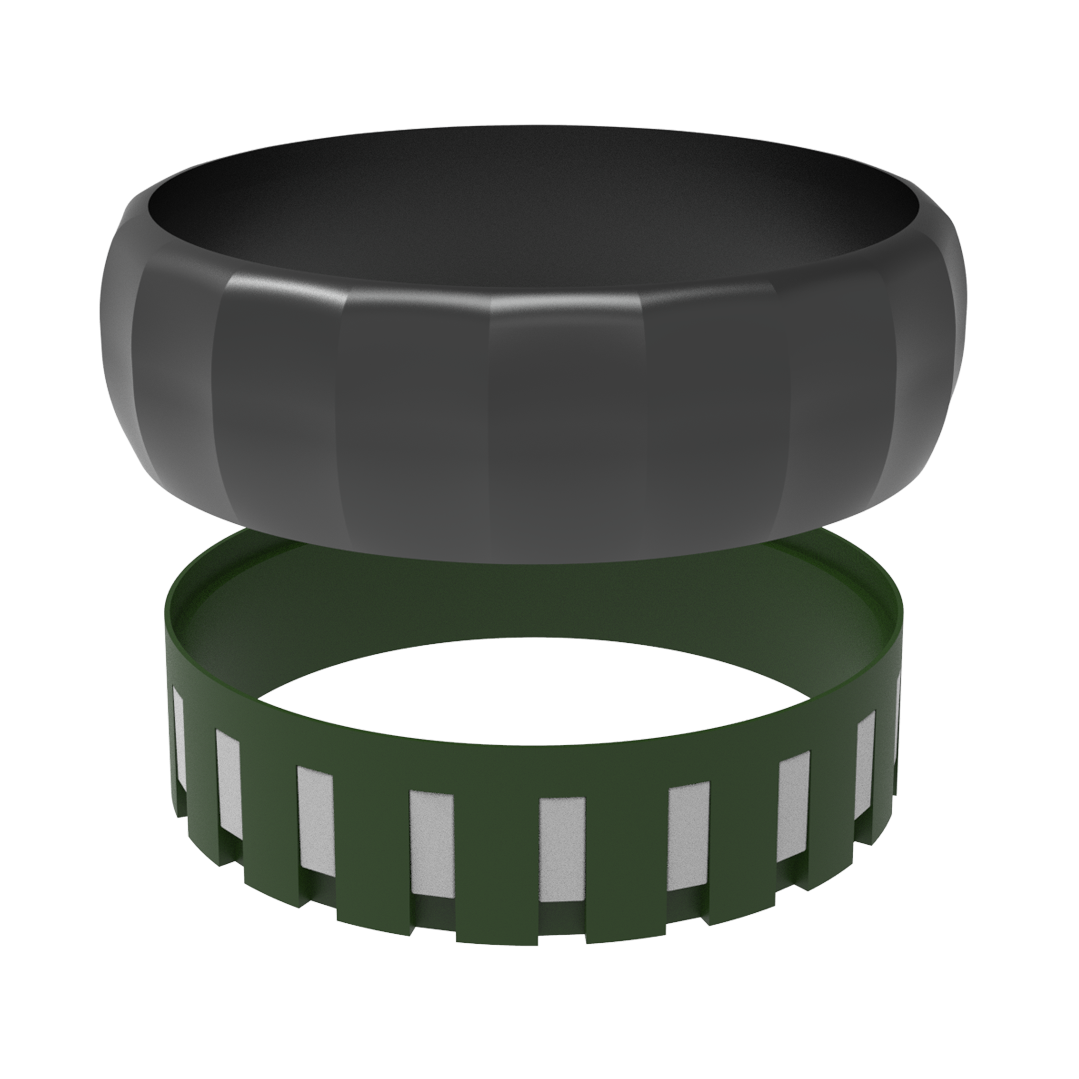

PREMIUM QUALITY, LOW COST

This high quality luxury product is set to be produced in collaboration with existing partners of Boretti. Close contact with said partners efficiently led to low cost production, even with the product’s low quantity production size.

Inside housing PCB snaphooks

Under display haptic engine press fit

Injection molded inner housing

Inside housing screw standoffs

Glass cover allignment edge

ITS IN THE DETAILS

A multitude of features are used to improve the manufacturability, regidity and ease of assembly. A single two-part injection molded core holds all other components together

DURABLE AND REPAIRABLE

Besides adding features and subassemblies to increase first and third party repairability, rigorous testing was done to validate the watertightness, fall and heat resistance of la Selce. Using multiple accurate prototypes (material and tolerance wise) durability is ensured.

All videos are made in collaboration with Art van Zuuk